T10C, The Powerful Upgrade from ALSTOM’s GT10B

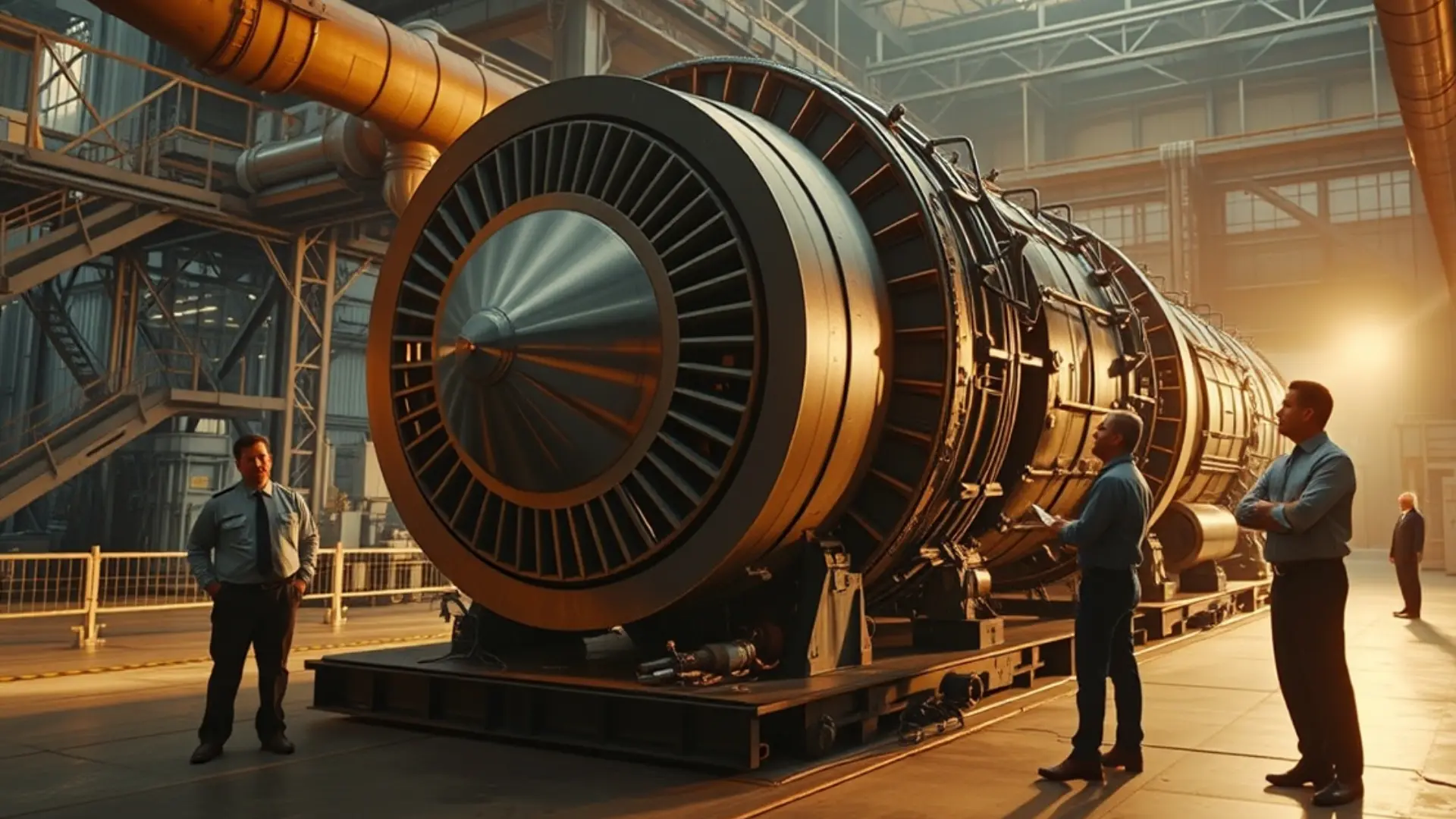

ALSTOM Power’s GT10C is a powerful industrial free turbine gas power plant is the latest technology, with an installed capacity of thirty megawatts, perfect for high utility industrial use. An upgrade from the GT10B gas turbine that produced 25MW, the GT10C is characteristic of increased reliability, power, and efficiency necessary for constant full load operation.

This state-of-the-art turbine is designed to greatly improve power generation, dependability, and efficiency in operations, establishing it as an essential energy resource for a range of industrial uses. As global energy requirements continue to grow and the demand for sustainable alternatives increases, this turbine offers industries a reliable means to fulfill their energy requirements while reducing environmental effects. ALSTOM’s commitment to innovation and efficiency is evident in this robust turbine design. Consequently, ALSTOM pays attention to the durability to make GT10C a worthwhile addition to the world of industrial gas turbines as well as employing innovative engineering.

Significance of the GT10C in Industrial Applications

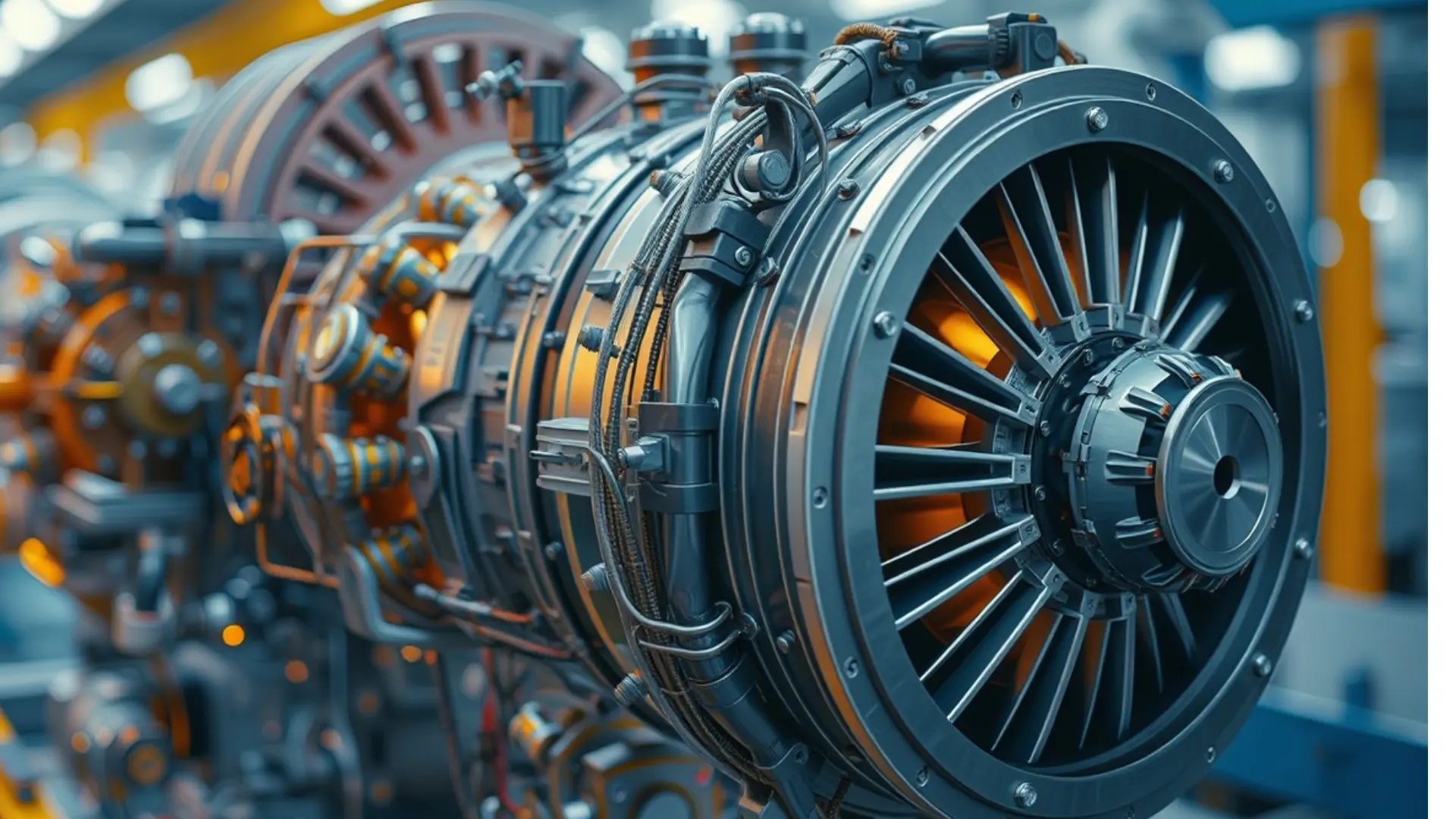

The GT10C is an advanced industrial gas turbine that was upgraded from the GT10B type and is primarily used for mechanical drive and power generation. Because of its 30 MW capacity and improved efficiency, it has become more and more common in a range of industrial applications, particularly in combined cycle and cogeneration settings. One of its most prominent characteristics is the Dry Low Emission (DLE) technology, which significantly reduces NOx emissions to 15 parts per million for gas and 42 parts per million for liquid fuels. As a result, the GT10C is an environmentally friendly option that meets industrial demands for lower emissions and better compliance with environmental regulations. The updated GT10C includes an 11-stage compressor as opposed to the 10-stage one found in the GT10B. The pressure ratio and mass flow are enhanced by this modification.

Key Features of the GT10C

- Increased Power Output: From 25 MW to 30 MW.

- Enhanced Efficiency: Optimized design for improved fuel consumption and operational performance in industrial applications.

- Advanced Control System: Features a state-of-the-art control system that ensures stability and efficiency under varying load conditions.

- Reliability and Durability: Engineered for consistent performance, enhancing reliability in demanding operational environments.

- Maintenance-Friendly Design: Simplifies servicing procedures, reducing downtime and boosting productivity through easier maintenance access.

- Improved Efficiency: Higher fuel efficiency and reduced emissions

- Optimized Combustor and Blades: Better combustion stability and temperature handling.

Technical Specifications of the GT10C

The GT10C’s technical specs demonstrate its potential as a top industrial gas turbine. With a 30 MW power output, it performs well in a variety of applications. With a 30 MW operating capacity, this power plant may be configured to run on a variety of fuels, including natural gas, making it appropriate for a wide range of industries. Due to its space-saving design and impressive power-to-weight ratio, this equipment can be integrated into current buildings. Constructed from durable materials, it is capable of enduring high temperatures and challenging conditions. Additionally, its performance metrics, including operational speed and load capacity, ensure that it can adapt to varying demands while maintaining reliability.

Design Improvements from the GT10B

The GT10C showcases ALSTOM’s commitment to innovation and efficiency through its upgraded design compared to the GT10B. Key advancements include enhanced turbine blades that boost aerodynamics and heat resistance, leading to better performance in demanding conditions. Furthermore, the cooling systems have been optimized to maintain optimal functionality across diverse environments, significantly reducing the risk of overheating. These enhancements not only improve the turbine’s reliability but also extend its operational lifespan. The overarching engineering approach emphasizes robustness while maintaining a lightweight structure, facilitating easier installation and maintenance.

Benefits of Upgrading to the GT10C

- Enhanced Efficiency: Notable decreases in fuel usage result in reduced operational expenses, benefiting overall financial performance

- Cost Savings: Greater efficiency results in lower energy costs, boosting the profitability of various sectors

- Environmental Compliance: The turbine’s exceptional environmental capabilities assist industries in adhering to strict emissions standards, fostering sustainable practices.

- Fuel Flexibility: Capable of accepting various fuel types, including natural gas and biogas, offering greater operational versatility.

- Reliable Energy Source: Ensures industries can depend on a powerful and efficient energy solution to meet growing energy demands responsibly.

Operational Efficiency and Fuel Economy

Enhanced Operational Efficiency and Fuel Savings The GT10C has achieved remarkable operational efficiency alongside improved fuel savings, leading to reduced operating costs. When compared to its predecessor, it delivers greater power with superior thermal efficiency while consuming less fuel. Its innovative design features advanced combustion technology that optimizes fuel usage and minimizes emissions. This approach not only addresses fuel consumption concerns economically but also promotes responsible energy consumption by reducing waste and pollution. The GT10C’s impressive fuel efficiency makes it an attractive option for industries seeking sustainable operational practices, indicating potential long-term cost reductions and environmental advantages.

Comparison with Competitor Turbines

Differentiation from Competing Turbines What distinguishes the GT10C from other turbines within the same capacity range is its exceptional combination of efficiency and performance. While several rival models may offer comparable power outputs, the turbine’s sophisticated control systems and innovative design typically ensure enhanced reliability during operation. Its versatility in accommodating various fuel types further enhances its competitive position, especially as industries transition toward greener energy solutions. With benefits such as lower emissions and decreased maintenance requirements, the GT10C has become a favored choice for organizations aiming to improve their energy strategies without sacrificing performance.

Environmental Impact and Emissions Reduction

Because GT10C uses improved combustion technology to produce significantly less pollution, safety—especially environmental safety—is a top priority. As a result, it can burn fuel more efficiently than usual and release fewer greenhouse gases, including carbon monoxide (CO) and nitrogen oxides (NOx). The GT10C is perfect for industries that care about the environment because it satisfies all of the requirements for gas emissions, making it responsive to international environmental standards. ALSTOM has shown that it wants to provide industries with a cleaner energy solution that will allow them to meet environmental requirements while also enjoying improved energy source performance thanks to its strict emissions control policy.

Operational Efficiency and Reliability

In the realm of industrial energy, achieving high operational efficiency and reliability is paramount, and the GT10C excels in both areas. The turbine integrates sophisticated monitoring and control systems within its design to optimize performance and ensure effective operation across various load conditions. Its versatility allows industries to maintain consistent output levels while minimizing the risk of downtime. Additionally, the turbine’s architecture is crafted to reduce the necessity for extended service outages by facilitating streamlined maintenance routines. With a solid reputation for reliability, it empowers businesses to operate with assurance as a dependable energy solution.

Environmental Impact of the GT10C

In today’s energy sector, the environmental implications of the GT10C are crucial. This turbine is engineered to comply with rigorous emissions standards, leading to a notable decrease in greenhouse gas emissions when compared to older models. Its impressive thermal efficiency means that less fuel is required to generate equivalent energy levels, thereby lowering carbon footprints. Furthermore, its flexible fuel usage allows for seamless integration with renewable energy sources, further mitigating environmental effects. By adopting this technology, companies can satisfy their energy needs while promoting sustainability efforts, contributing to a greener future.

Cost Analysis of the GT10C

A cost analysis reveals its potential for long-term savings and operational efficiency. Although the initial expenditure may be larger than for prior versions, the turbine’s increased efficiency and reduced fuel use over time lead to significant savings. The total cost of ownership is further decreased by fewer operating disruptions brought on by decreased maintenance requirements and increased dependability. Additionally, the GT10C’s lower emissions can assist avoid possible regulatory charges as firms place a greater emphasis on sustainability. It is a sensible option for industrial applications because, all things considered, the financial advantages of implementing it greatly exceed the initial outlay.

Installation and Integration Process of GT10C

The installation and integration process of the GT10C turbine is designed to be efficient and straightforward. Because of its small size, the turbine can be installed in a variety of ways that can be customized to match existing facilities. Installation usually entails alignment, site preparation, and system connection, all of which are handled by ALSTOM’s skilled teams. During the integration phase, it is essential to ensure that the turbine is compatible with existing equipment and control systems. Effective installation plays a vital role in maximizing performance, and ALSTOM offers extensive support throughout this process to guarantee optimal turbine operation from the outset.

Customer Support and Maintenance Services

ALSTOM’s customer support and maintenance services for the GT10C are crucial for achieving long-term operational success. The company provides a variety of services such as routine maintenance inspections, troubleshooting assistance, and performance evaluations. Their skilled technicians are trained to quickly resolve any issues that arise, thereby reducing downtime and ensuring consistent productivity. Furthermore, ALSTOM offers training programs for staff to familiarize them with best practices in turbine operation and maintenance. This dedication to customer support not only extends the lifespan of the turbine but also cultivates strong relationships with clients, contributing significantly to their success.

Future Developments and Upgrades for the GT10C Series

Looking ahead, ALSTOM Power is focused on innovation, with plans for future upgrades to the GT10C series already underway. These enhancements aim to improve productivity, reduce emissions, and incorporate further automation features. By enhancing the GT10C’s capability to tackle emerging energy challenges, ALSTOM intends to keep this model at the leading edge of gas turbine technology as advancements continue. Research initiatives within ALSTOM prioritize sustainable energy production, ensuring that the GT10C series evolves alongside industrial and environmental requirements in the coming years.

Conclusion

ALSTOM Power’s GT10C industrial gas turbine is well-suited for major industrial applications across global markets. Its enhanced capacity, reliability, and versatility across various operating scenarios distinguish it within the 30 MW turbine category. Moreover, ALSTOM’s commitment to safety, sustainability, and innovation will elevate the importance of the GT10C in various industries. With its outstanding performance and ongoing advancements, it is poised to remain a primary power source in future energy markets.